RAIL TANKER

EXTERNAL CLEANING (WASHING, RINSING, DRYING)

COMPLEXES

The problem of railway tanker cleaning is traditionally solved worldwide by steaming and spray rinsing with hot washing solution (or water), which initially has several significant disadvantages:

1) huge following operating costs related to:

- high temperature of the cleaning water (more than 90°C);

- high pressure of the used water (more than 10–15 MPa);

2) high complexity and cost of water treatment.

Developed and presented by «CTG» modern closed recirculating cleaning technology, using highly efficient washing reagents and having a compact design, is an absolute alternative to the traditional resource-intensive steaming technologies, even of foreign manufacture, and is called a washing and recirculation technology (WRT). These technologies ensure the cleaning of railway tankers from the transported petroleum products before the necessary maintenance work and possible product changes, e.g. for high-quality petroleum products.

Presented by «CTG» modern washing and recirculation technology (Patent EP1389229 and RF Patent № 2200637) for cleaning of contaminated surfaces ensures the compliance with all requirements for the quality of LCC treatment and ecological safety of the technological processes used.

It is necessary to emphasize that there are no analogues to such compact and resource-light cleaning systems in the world. Foreign proposals are about high resource consumption and complex water purification system that pays for itself only through the creation of washing and steaming complexes with the capacity of several hundred tank cars per day. Proposals by «CTG» provide significant efficiencyandlow performance (several tank cars per day), that makes them extremely attractive, particularly for equipping car-repair factories, depots, etc.

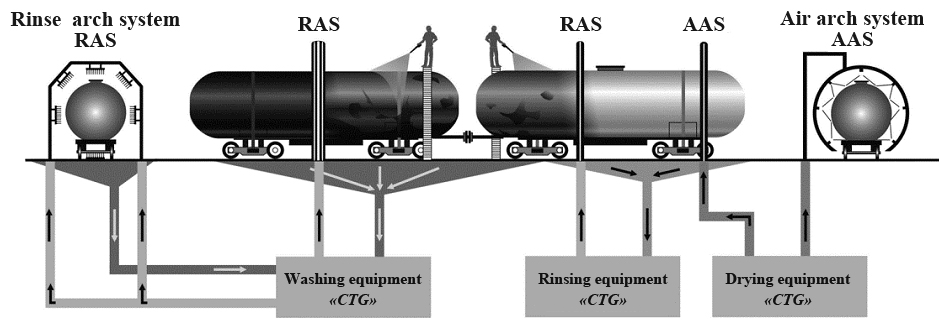

The environmentally safe resource-saving cleaning technology for the external surfaces of railway tankers is schematically presented below:

The «CTG» equipment, used for the operation of washing and recirculation technology treating tank cars consists of the main technological and peripheral equipment, appropriate combinations of which allow to solve various problems. The main process equipment itself consists of separate modules, each of which performs part of the process.

RAIL TANKER

EXTERNAL CLEANING (WASHING, RINSING, DRYING)

COMPLEXES

AUTOMATICALLY CONTROLLED

KNO-JCa

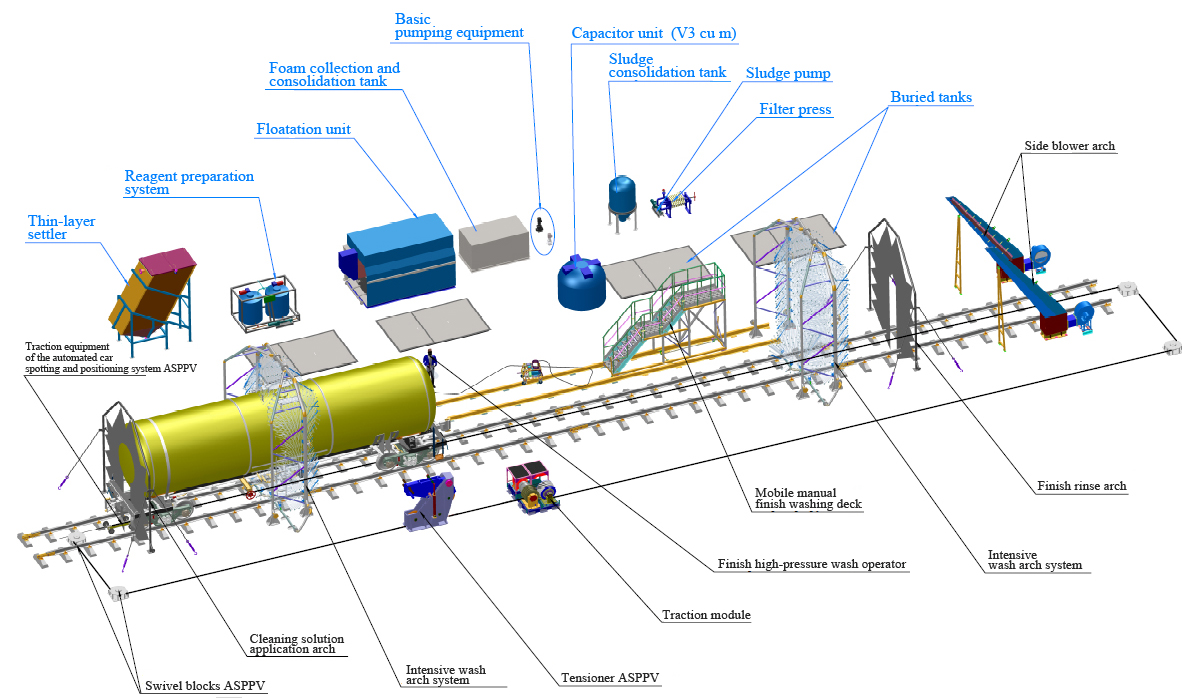

The KNO-JCa complex is designed for the automatic external cleaning of rail tank cars from various contaminants. In this complex the tanker undergoes applying the cleaning solution, intensive washing of the external surfaces, intensive rinsing, finishing rinse and blowing-off excess moisture while moving through the treatment arches. In case of the tanker being heavily contaminated the process may require manual cleaning.

To comply with the water consumption and sewage water rate, as well as to save water, the complex is equipped with the circulating water purification and preparation system.

Specifications of the

complex KNO-JCa

|

№ |

Technical characteristics |

Unit of |

Value |

| 1. |

Efficiency |

units/day |

up to 50 |

| 2. |

Dimensions - length |

mm |

66000 |

| 3. |

Installed electrical power |

kW |

285,00 |

| 4. |

Water consumption for technical needs |

m3/day |

7,5 |

| 5. |

Coolant rate |

GCal/day |

7,14 |

| 6. |

Compressed air flow |

m3/day |

0,05 |

| 7. |

Maintenance manpower |

person/shift |

4 |

RAIL TANKER

EXTERNAL CLEANING (WASHING, RINSING, DRYING)

COMPLEXES

SEMI-AUTOMATICALLY CONTROLLED

KNO-JCpa

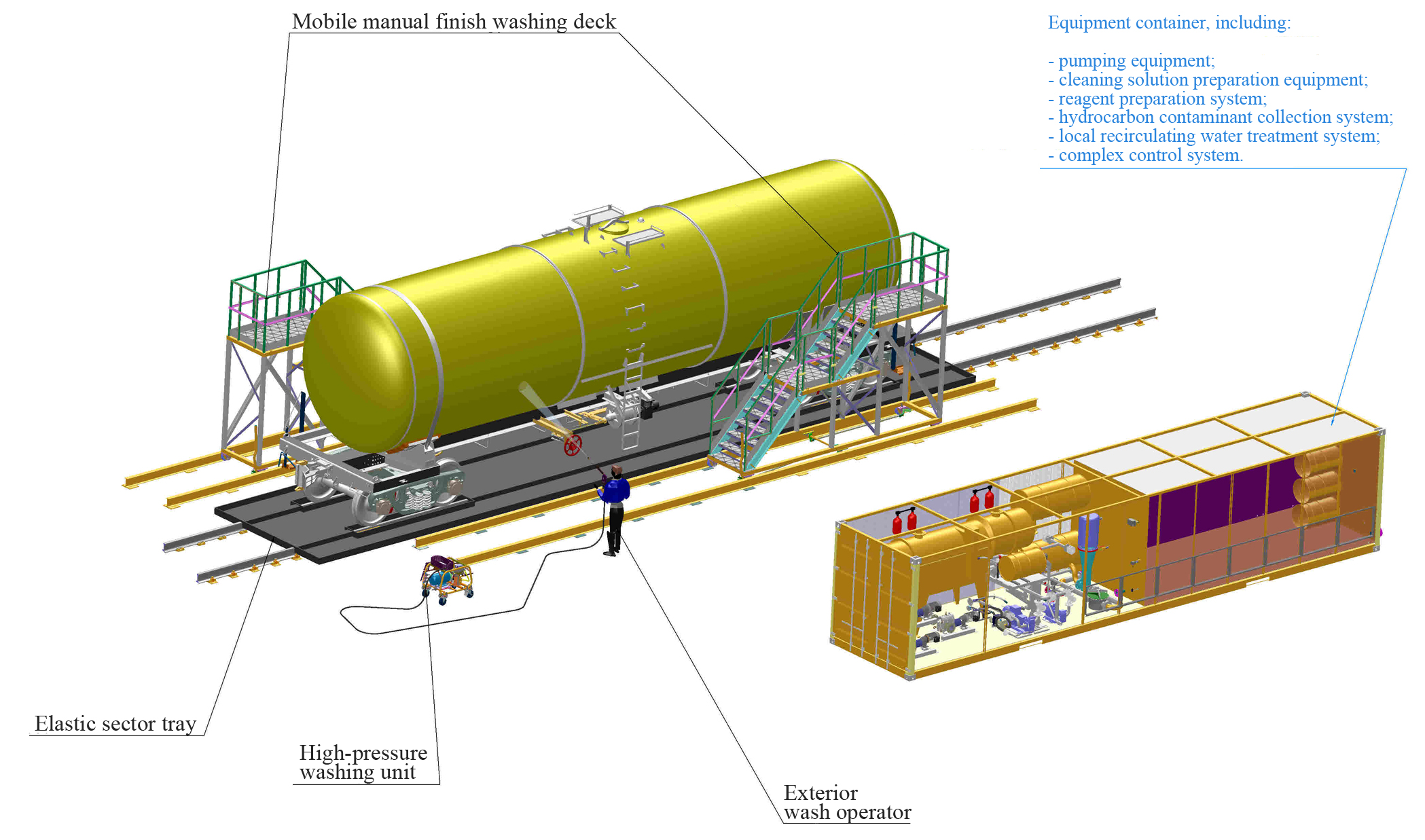

The KNO-JCpa complex is designed for the automatic external cleaning of rail tank cars from various contaminants. In this complex the tanker undergoes applying the detergent, rinsing and blowing-off excess moisture while moving through the treatment arches. The contaminants are removed from the tank cars by means of the high-pressure apparatus.

To comply with the water consumption and sewage water rate, as well as to save water, the complex is equipped with the circulating water purification and preparation system.

Specifications of the

complex KNO-JCpa

|

№ |

Technical characteristics |

Unit of |

Value |

| 1. |

Efficiency |

units/day |

up to 12 |

| 2. |

Dimensions - length |

mm |

36000 |

| 3. |

Installed electrical power |

kW |

80,00 |

| 4. |

Water consumption for technical needs |

m3/day |

1,80 |

| 5. |

Coolant rate |

GCal/day |

3,00 |

| 6. |

Compressed air flow |

m3/day |

0,05 |

| 7. |

Maintenance manpower |

person/shift |

3 |

RAIL TANKER

EXTERNAL CLEANING (WASHING, RINSING, DRYING)

COMPLEXES

MANUALLY CONTROLLED

KNO-JCna

The KNO-JCna complex is designed for the automatic external cleaning of rail tank cars from various contaminants using high-pressure apparatus. The complex is equipped with the mobile circulating water purification and preparation system.

Specifications of the

complex KNO-JCna

|

№ |

Technical characteristics |

Unit of |

Value |

| 1. |

Efficiency |

units/day |

до 8 |

| 2. |

Dimensions - length |

mm |

18000 |

| 3. |

Installed electrical power |

kW |

55,00 |

| 4. |

Water consumption for technical needs |

m3/day |

1,2 |

| 5. |

Compressed air flow |

m3/day |

0,05 |

| 6. |

Maintenance manpower |

чел./смену |

1 |

If you have questions about our washing complexes, please contact us, our coordinates are listedon the Contact page, andalsoviathe order form.