UNDERCARRIAGE

TROLLEY FRAME

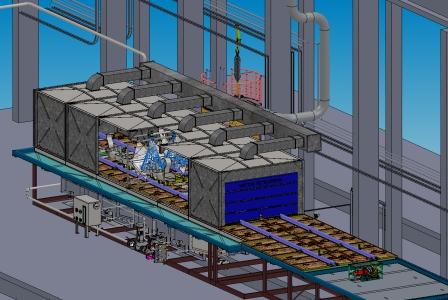

CLEANING COMPLEX

KRT

It is a known fact that the cleaning of undercar trolley frames is an essential procedure during the repair of cars. Currently used technologies are associated with high costs, long processing time, and the technical complexity of the devices. The high costs are made up from extremely high initial capital costs and operating costs. From this perspective it is desirable to replace the traditional cost- and resource-demanding technology with a cost-effective alternative, that improves the quality of cleaning and corrosion protection of the surfaces, and allows to organize the process itself closed (circuit, no discharge), and at the same time complying with all environmental regulations.

The experts of the company «CTG» have developed a special complex for cleaning undercar trolley frames of all types and large parts with complex geometries in standalone mode, that provides high efficiency treatment of contaminated surfaces in the resource-saving environmentally safe mode.

The complex consists of 3 main systems:

- equipment for heating, preparing and purifying the detergent;

- cleaning mechanisms located in the washing chamber;

- conveyor track for moving the parts while treated.

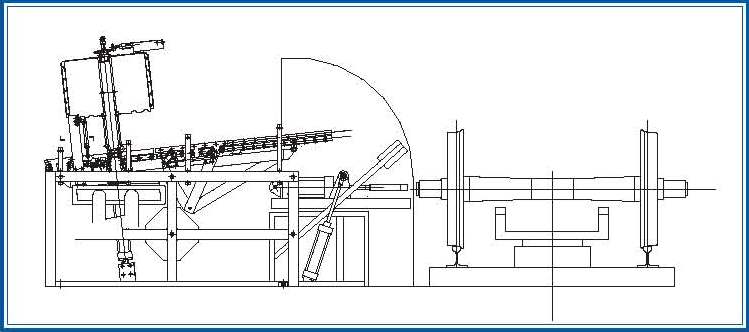

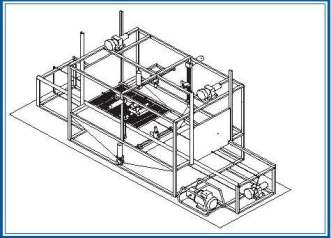

The structure of the complex for cleaning undercarriage trolleys

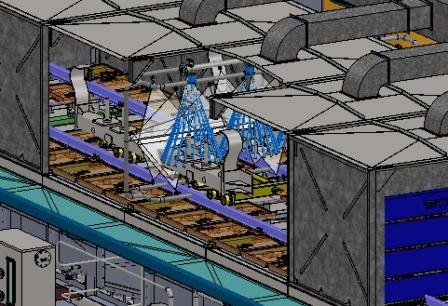

The transporting trolley and the washing mechanism carriage speeds are coordinated so that the nozzle jets treat every point of the surface.

Our washing complexes are designed so that it is possible to quickly reconfigure the system and create more efficient washing algorithms or switch to another product.

|

Technical characteristics |

Unit of measurement |

Value |

|

Dimensions |

mm, not more than |

|

|

The number of installed nozzles |

pieces |

2 |

|

Installed weight with the working solution |

kg |

140 |

|

Operating pressure of the solution |

mPa |

16 |

|

The rotation speed of the washing mechanism |

mps |

0,2 |

|

The speed of the transporting trolley |

mps |

0,05-0,1 |

|

Total travel of the transporting trolley |

mm |

24000 |

|

The length of the washing chamber |

mm |

11000 |

|

Dimensions of the piece in process |

mm |

|

SUBWAY CAR TROLLEY

FRAME AND UNITS AND

OTHER UNDERCAR EQUIPMENT

CLEANING COMPLEX

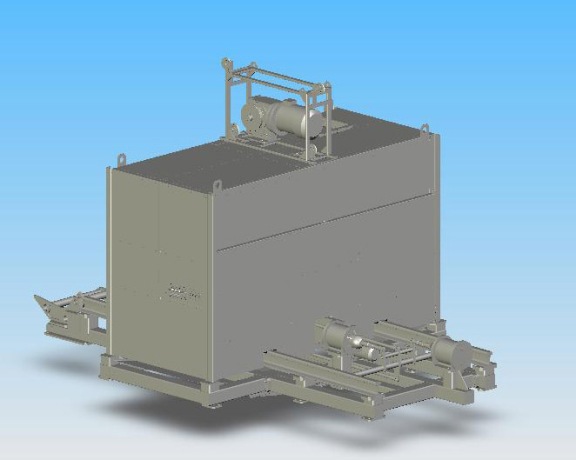

The complex is designed for cleaning undercar trolley frames of all types and large parts with complex geometries in standalone mode.

The complex consists of:

- sectional washing chamber with the flat and spin washing arch systems and the combined extract-and-input ventilation.

- transporting mechanism, including:

- traction unit,

- transport trolley,

- rail track,

- platform for the parts -

process equipment for preparing, heating, purifying and feeding the solution, including:

- filtration and separation units,

- heating systems,

- expendable and storing vessel equipment,

- pumping equipment with shutoff and control valves. - control systems.

|

|

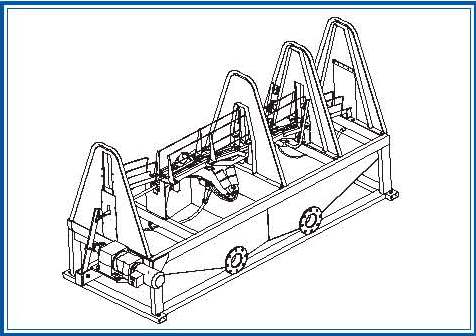

WHEEL SETS

DISASSEMBLING AND CLEANING

COMPLEX

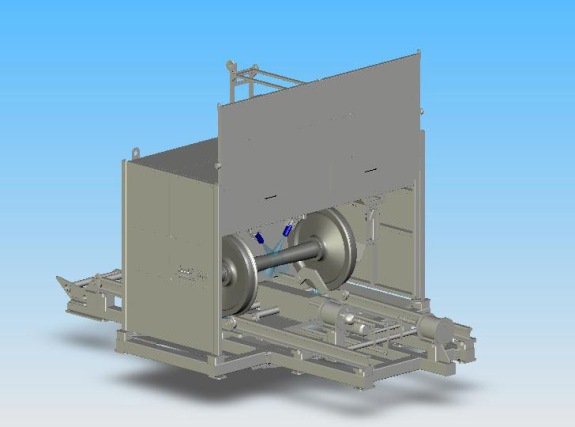

The wheel sets cleaning line (LO-KP) is a metal structure with the rail track, under which is installed the tray for collecting the cleaning solution waste. The washing complex consists of a transport line and a cleaning chamber with control valve stack.

The washing chamber includes a housing in which there are four cleaning mechanisms; two for the wheel sets internal surfaces and two for the external surfaces washing. The washing chamber is equipped with a mechanism for lifting the curtains that moves the two curtains in the vertical direction along the shank guides.

Schematic structure of the complexes for wheel sets disassembly and cleaning

The complex has the following equipment:

|

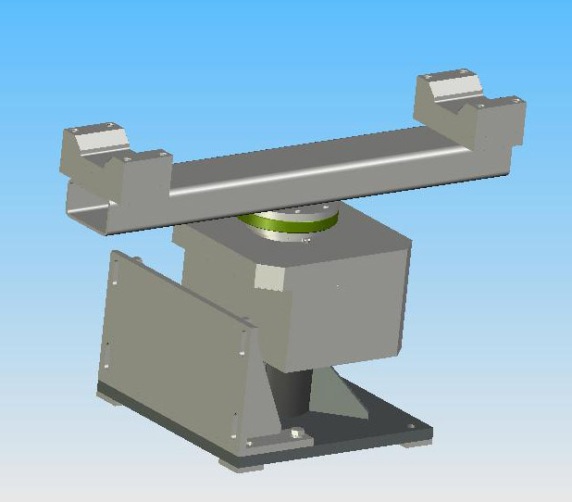

WHEEL SETS LIFT Pk-KP This unit is designed for dismount the axle box on the wheelset. |

|

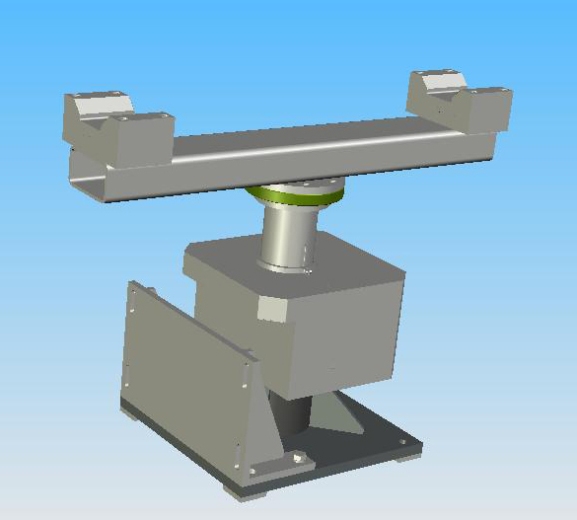

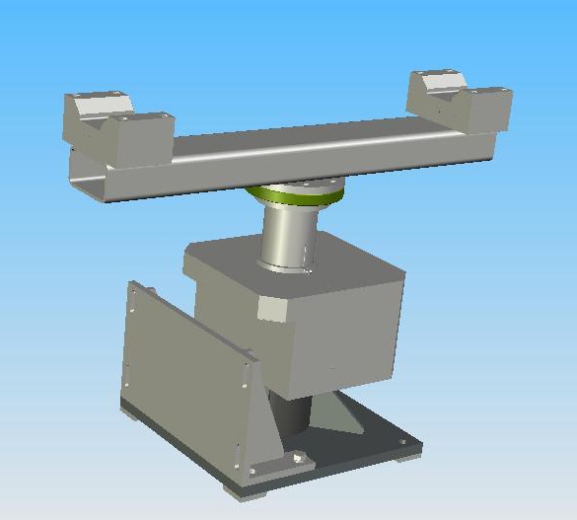

WHEEL SETS TURNTABLE PvS-KP The device is intended to guide the passage of the wheelset during its processing cycle. |

|

WHEEL SETS LIFT AND TURN TABLE PpS-KP It is a lifting-turning mechanism. Its difference from the wheel sets turntable is the presence of the swing drive. |

|

WHEEL SETS WASHING MACHINE LO-KP The machine is designed for cleaning of the wheel sets with the raceway contact diameter 950 ± 100 mm in automatic or semi-automatic mode |

|

|

Technical characteristics |

Unit of |

Value |

|

One car processing time |

min |

1-5 |

|

Dimensions: 1) pallet systems |

mm, |

2591 |

|

The number of installed nozzles |

pieces |

60 |

|

Installed power |

kW |

230 |

|

Power demand |

kW |

200 |

|

Operating pressure |

mPa |

0,8-1,0 |

|

Performance of the pumping equipment |

l/min |

up to 1200 |

|

Estimated consumption of propylene glycol |

l/car |

6-10 |

|

Installed weight with the working solution |

t |

not more than 50 |

Together with the above mentioned equipment the complex for wheel sets disassembly and cleaning contains the following components:

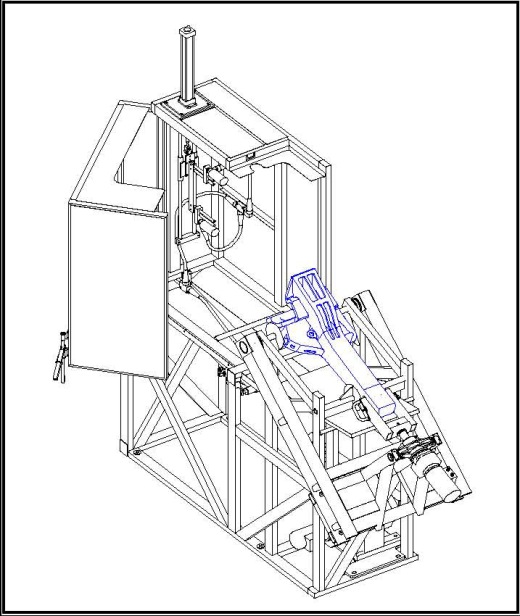

MACHINE

FOR REMOVING THE AXLE-BOX BODIES

AND PRESSING OUT THE BEARING

MD-BP

Designed to remove the axle box from the wheelset, dissemble it and send the components down the line to the washing machines. Its dimensions are 4500x1400x1650 mm.

AXLE-BOX BODIES AND PARTS

WASHING MACHINE

MM-BD

Designed for cleaning of various parts with dimensions up to 800x800x1300 mm and weighing up to 300 kg.

The pallet crate for the parts as well as 4 moving high-pressure nozzles allows washing and cleaning the parts from all sides.

The required quality of cleaning is provided by adjusting the nozzles and the feed table movement speeds.

BEARING WASHING, RINSING

AND DRYING MACHINE

UM-P

Designed for washing, rinsing and drying the bearings in automatic mode, its dimensions are 5100x1800x1600 mm.

COUPLING DEVICE

WASHING MACHINE

MM-SU

The machine is designed for cleaning of the automatic coupling device SA-3 and its analogues in semi-automatic mode, its dimensions are 2200x1400x1600.

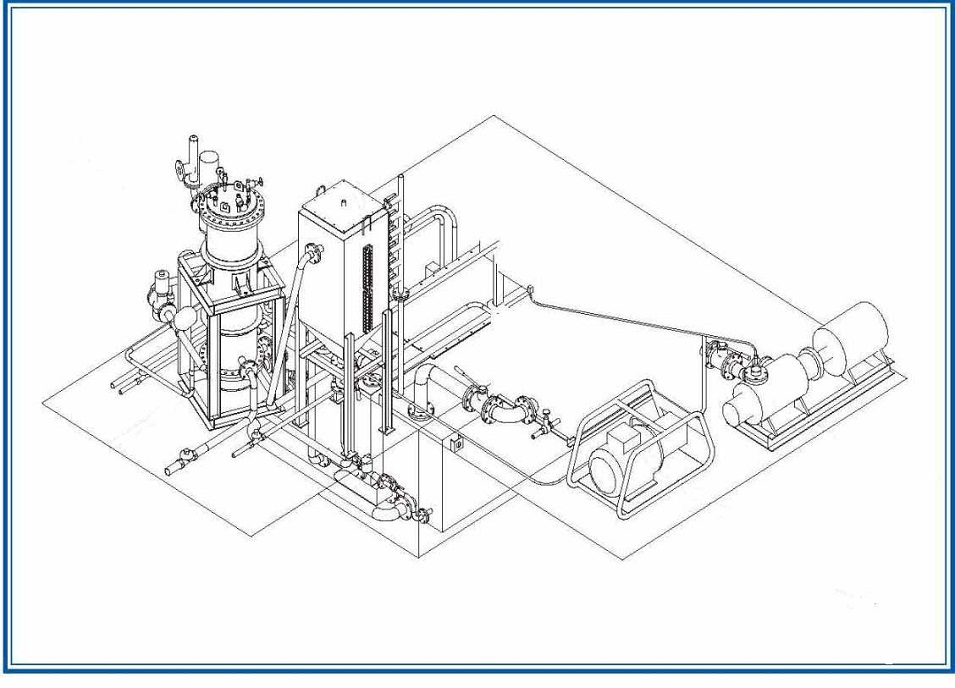

THE CLEANING SOLUTION PREPARING

AND PURIFYING COMPLEX

KTO-POMR

It includes the following equipment:

1. Solution flash separator;

2. Cleaning solution supply tank;

3. Sludge tank;

4. Machine for manual cleaning;

5. The pump pressure module.

Schematic structure of the cleaning solution preparing and purifying machine

For detailed information on the washing complexes for the undercarriage equipment you can contact us at the coordinates listed on the page «contacts», or ask your questions through the order form.