RAIL TANKER

INTERNAL WASHING

COMPLEXES

FROM STABLE GAS CONDENSATES

KVO-JCgk

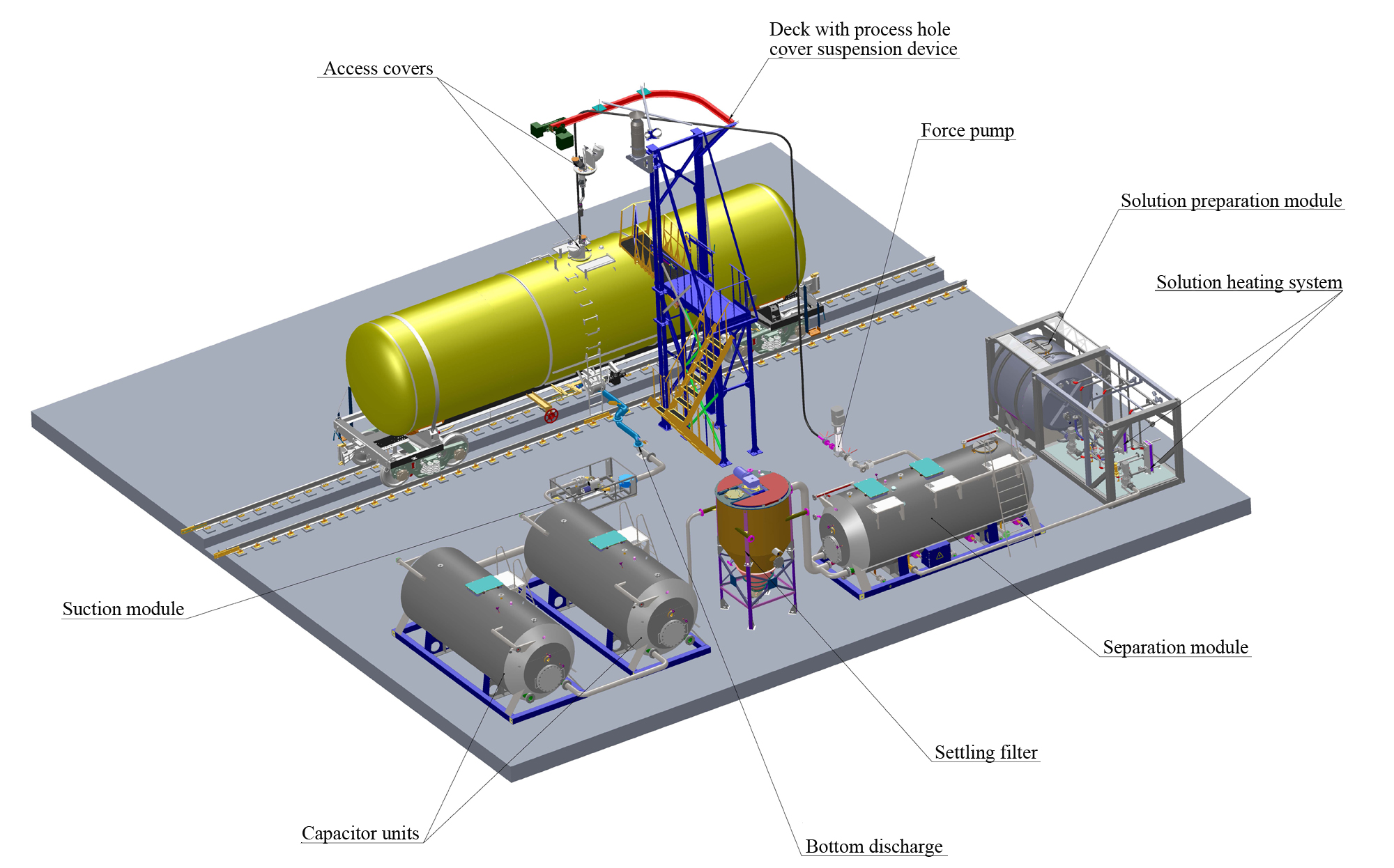

The KVO-JCgk complex is designed to clean the inside surfaces of the railway tankers from stable gas condensates in the resource-saving environmentally safe closed mode.

The need to develop and implement individual washing technology to clean the tankers from stable gas condensates is connected with the specifics of this type of liquid hydrocarbon, that considerably differs from the other petroleum products. Internal tanker cleaning from stable gas condensates is complicated by the high content of the asphaltene-resin-paraffin deposits with the melting temperature of 50–70°C, which are deposited on the tanker walls and bottom, as well as by the need to prevent the formation of atmospheric explosives, that may be caused by heating the residues of the stable gas condensate.

Complexes KVO-JCgk can have various efficiency (12, 25, 50, 75, 100, 150, 200 or more units per day), equipment and the automation degree.

Specifications of the

complex KVO-JCgk

|

№ |

Technical characteristics |

Unit of |

Value |

|

1. |

Efficiency |

units/day |

12 |

|

2. |

Minimal dimensions of site for placement of equipment - length |

mm |

18000 |

|

3. |

Installed electrical power |

kW |

81,25 |

|

4. |

Water consumption for technical needs |

m3/day |

0,45 |

|

5. |

Coolant consumption |

GCal/day |

1,32 |

|

6. |

Compressed air consumption |

m3/day |

1,65 |

|

7. |

Number of service stuff |

person/shift |

2 |

If you have questions about our equipment, please contact us, our coordinates are listedon the contact page, andalsoviathe order form.