RAIL TANKER

INTERNAL WASHING

COMPLEXES

FROM HIGHLY PARAFFINIC CRUDE

KVO-JCnv

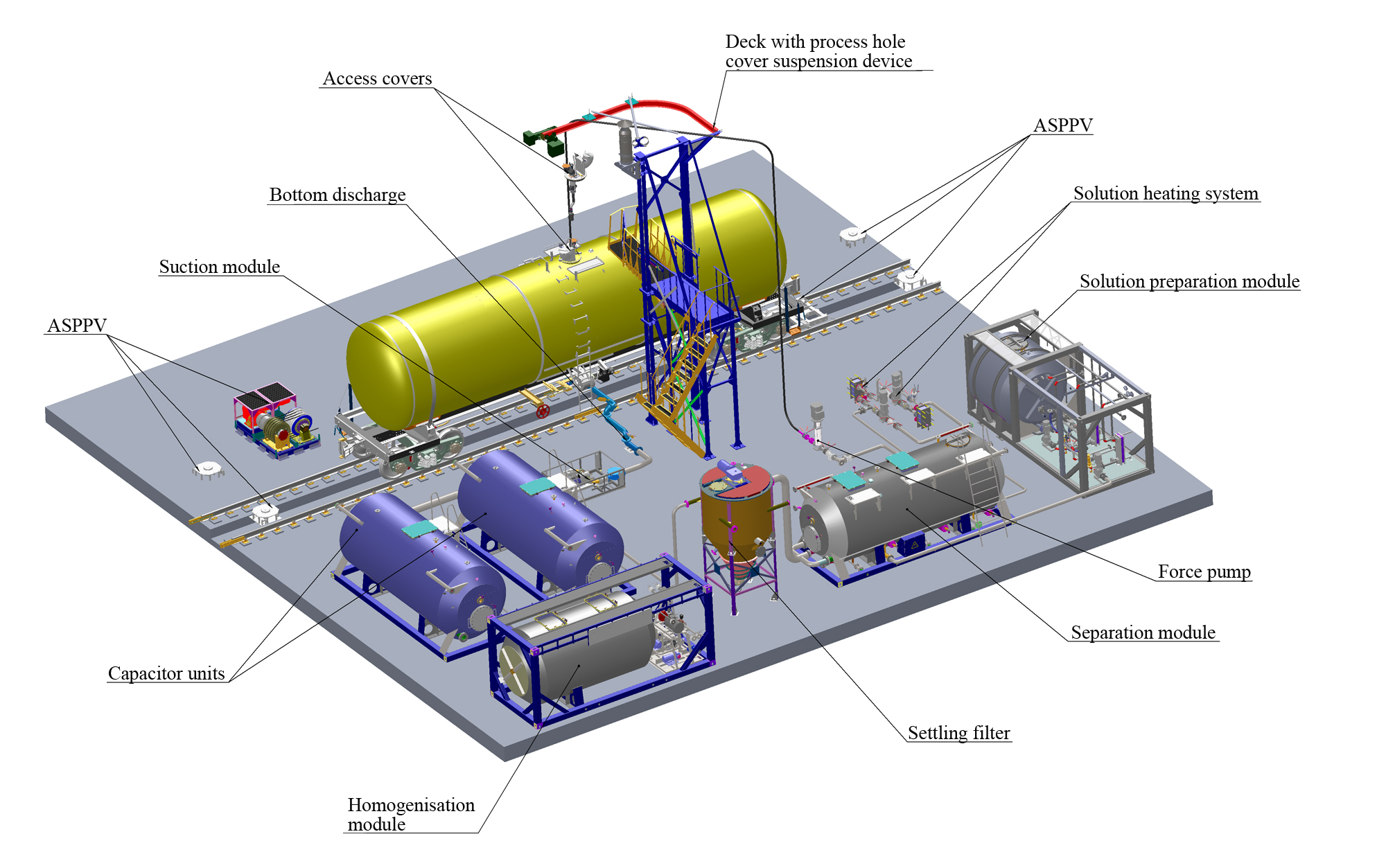

The KVO-JCnv complex is designed to clean the inside surfaces of the railway tankers from highly paraffinic crude in the resource-saving environmentally safe closed mode.

Developed by «CTG» cleaning technology is based on removing high-viscosity-index oil using the specially designed process cover with two washing machines. During the first step the residue is removed from the lower half of the tanker by the aqueous solution of the «O-BISM» detergent, warmed up to the operating temperature. The second step is the treatment of the entire tanker (final cleaning). If necessary, the end butts of the tanker are cleaned separately by the aqueous solution of the «O-BISM» detergent under pressure, coming through a specially designed nozzle cap in the process cover. At the final stage of the process the tankers are degassed, dried and cooled. The combination of optimal pressure, temperature and aqueous detergent usage parameters, the unique properties of the detergent and the appropriate equipment makes it possible to clean tankers from highly paraffinic crude and viscous petroleum products and prepare them for repair or for filling.

Specifications of the

complex KVO-JCnv

|

№ |

Technical characteristics |

Unit of |

Value |

| 1. |

Efficiency |

units/day |

12 |

|

2. |

Minimal dimensions of site for placement of equipment - length - width |

mm |

18000 9000 |

|

3. |

Installed electrical power |

kW |

81.25 |

|

4. |

Water consumption for technical needs |

m3/day |

0.45 |

|

5. |

Coolant consumption |

GCal/day |

1.32 |

|

6. |

Compressed air consumption |

m3/day |

1.28 |

|

7. |

Number of service stuff |

person/shift |

2 |

If you have questions about our equipment, please contact us, our coordinates are listedon the contact page, andalsoviathe order form.