AUTOMATED SYSTEMS

FOR MOVING AND POSITIONING

RAIL CARS

ASPPV

Automated systems for moving and positioning rail cars (ASPPV) are designed for для moving and positioning sets of cars namely tanker cars, freight cars, gondola cars, passenger cars and other types of rolling stock.

ASPPV can be installed in indoor areas and on access ways. A traction module of direct or reverse stroke type on depending technological requirements can be used in all the cases.

Unlike shunting locomotives, ASPPV used for washing rolling stock allows convoys be moved with uniform speed to provide the qualitative washing in accordance with a specific technological process. This speed for washing electriс trains and passengers cars are equal to 0,6-0,9 km/hour and 1-1,5 km/hour, correspondingly. In comparison. the minimal speed stipulated by rules of JSC Russian Railways is equal to 1,5 km/hour, which does not provide the required quality of washing.

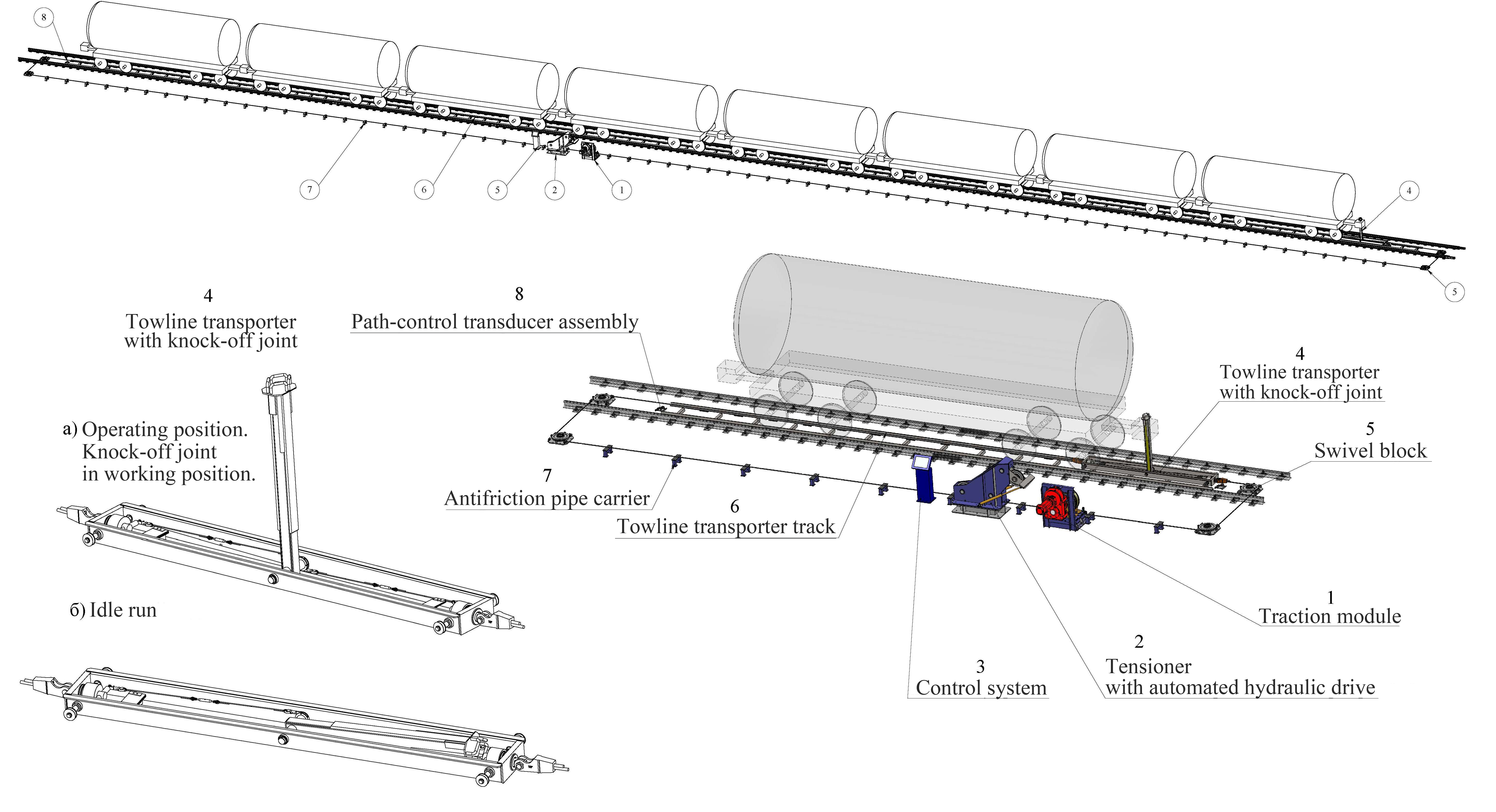

Example of an automated system for moving and positioning

The advantage of such shunting systems is the automation of technological operations of moving a rolling stock Automated systems for moving and positioning are delivered with management systems, control panels, audible alarm signaling.

The justification od choosing a specific automated system for moving and positioning is defined in the process of designing and it allows all the costs while implementing the system to be optimized.

AUTOMATED SYSTEM

FOR MOVING AND POSITIONING CARS

UNIVERSAL

ASPPV-U

|

This system is designed for moving and positioning freight and passenger cars as well as electrical trains through washing complexes. It allows a set of 16 empty cars be moved at least. The movement is carried out by means of contacting between working rollers of a truck and wheel flange.

The system includes a traction module, a truck, blocks, stops for limiting the movement of a truck and installing in working position etc. This system can act in a large speed range.

| Technical characteristics | Unit of Measurement | Value |

| Length stroke | m | 90 |

| Rope traction effort of a pulling winch | Н | up to 60 000 |

| Rope traction effort of a back winch | Н | up to 80 000 |

| Electric drive capacity | kW | 19 |

| Weight of the product | kg, not more than | 6 200 |

AUTOMATED SYSTEM

OF TERMINAL TYPE

FOR MOVING AND POSITIONING CARS

ASPPV-Gt

This system is designed for one-direction moving and positioning freight cars through washing complex.It allows a set of four empty cars be moved through complexes without open passage.

The system includes a traction module, a truck, blocks, rope supports, stops for limiting the movement of a truck etc. This system can act in a large speed range.

A truck is moved along 1520 mm rail track. Truck design allows contact stress between working roller and wheel flange while moving convoys of heavy capacity be reduced.

| Технические параметры | Размерность | Значение |

| Length stroke | M | 90 |

| Rope traction effort of the main drum | Н | up to 50 000 |

| Rope traction effort of the auxiliary drum | кН | up to 5 |

| Electric drive capacity at DF=40% | Kw | 3,2 |

| Weight of the product | kg, not more than | 10 000 |

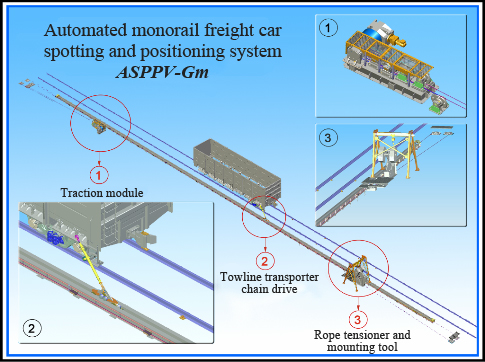

AUTOMATED SYSTEM

OF REVERSE TYPE

FOR MOVING AND POSITIONING CARS

ON AUXILIARY MONORAIL

ASPPV-Gm

This system is designed for moving and positioning freight cars under space-limited working conditions, it allows construction-and-erection operations while reconstruction objects be reduced. This system provides the movement of at least four empty cars. The movement is carried out by towing with using towing brackets or car rings.

The system includes a traction module, a carriage, monorail, a guide block, a tensioning device, hoisting device, support etc. This system can act in a large speed range.

|

Technical characteristics |

Unit of Measurement | Value |

| Length stroke | m | 90 |

| Traction effort (working load) | Н | 16 400 |

| Speed | m/s | 0,02-0,2 |

| Electric drive capacity | kW | 3 |

| Number of freight cars to be moved | pcs | 3 - 4 |

| Weight of the product | kg, not more than |

28700 |

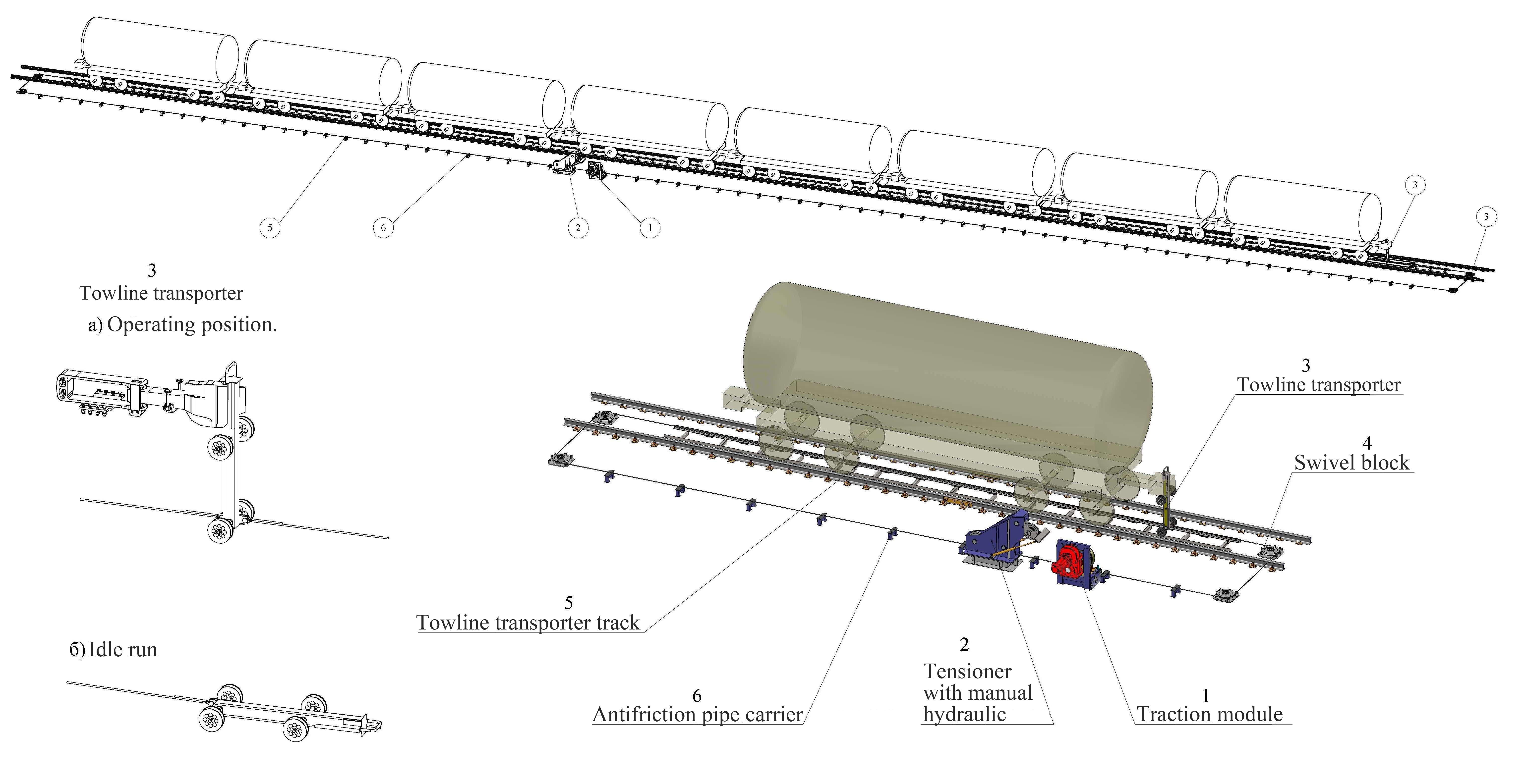

AUTOMATED SYSTEM

OF REVERSE TYPE FOR

MOVING AND POSITIONING CARS

ON TWO AUXILIARY MONORAILS

ASPPV-G2m

|

|

This system is designed for moving and positioning freight cars. It allows up to 12 freight cars be moved on washing complexes under ant working conditions. The movement is carried out by means of contact arrest stops of carriages and side frames of car carriage.

The system includes a traction module, a carriage, a guide block, a tensioning device, support, deck floor, bridge etc. This system can act in a large speed range.

The peculiarities of ASPPV-G2m are as follows: improved ergonomics, adjustable speed of movement, space between the rails is not occupied, may be operated in wide velocity range.

|

Technical characteristics |

Unit of Measurement | Value |

| Length stroke | m | 90 |

| Traction effort (working load) | Н | 57 000 |

| Speed | m/s | 0,2 -0,3 |

| Electric drive capacity | kW | 11 |

| Number of freight cars to be moved | pcs | 10 - 12 |

| Weight of the product | kg, not more than |

28 700 |

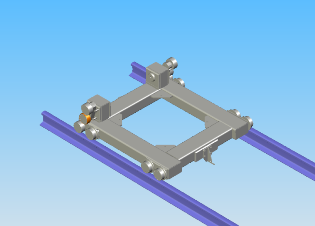

AUTOMATED SYSTEMS

OF REVERSE TYPE FOR

MOVING AND POSITIONING CARS

ON TWO AUXILIARY MONORAILS

ASPPV-G & ASPPV-G-R

|

|

The system is designed for moving and positioning freight cars. It allows up to 25 empty cars be moved.

The movement is carried out with using auxiliary rails by means of contact between traction trucks and working taping lines of wheels. As the result, while moving heavy-capacity convoys the danger to deform the wheel flange is avoided. .

The system includes a traction truck, a block, a device for measuring rope tension, a deflecting roller, a truck way, a control cabinet, a rack etc.

The peculiarities of ASPPV-G are as follows: improving ergonomics, optimal optimization of a process, a possibility to automate operations for hooking wagons, adjustable speed of movement.

| Technical characteristics | Unit of Measurement | Value |

| Length stroke | m | 90 |

| Traction effort (working load) | Н | 70 000 |

| Speed | m/s | 0,15-0,45 |

| Electric drive capacity | kW | 22 |

| Number of freight cars to be moved | pcs | 20 - 25 |

| Weight of the product | kg, not more than |

16 000 |

ASPPV-G-R is a version of ASPPV-G this system is equipped with the automated system of hooking wagons and radio control box.

The peculiarities of ASPPV-G-R are as follows: improving ergonomics, automation of hooking wagons, speed of movement can be regulated.

| Technical characteristics | Unit of Measurement |

Value |

| Length stroke | m | 90 |

| Traction effort (working load) | Н | 70 000 |

| Speed | m/s | 0,15-0,45 |

|

Electric drive capacity, including - Traction module (movement drive) |

kW |

30 22 |

| Number of freight cars to be moved | psc | 20 - 25 |

| Weight of the product | kg, not more than | 16 000 |

AUTOMATED SYSTEM

FOR MOVING AND POSITIONING

(ASPPVc)

The system is designed for moving and positioning any rolling stock with using the hooking device СА-З. The system includes a truck, truck way, traction module, traction rope, swiveling block, gui are as follows: de blocks etc. This system can act in a large speed range.

The peculiarities of ASPPVc are as follows: moving along rail way; the movement is carried out by means of hooking last cars in the set, guide block; a guide slot is required for a hook assembly; erecting a truck should be carried out for passing a convoy; erecting is very simple.

|

Technical characteristics |

Unit |

Value |

| Length stroke | m | up to 90 |

| Traction effort (working load) | Н | up to 50 000 |

| Electric drive capacity | kW | 11 |

| Weight of the product | кг, не более | 10 000 |

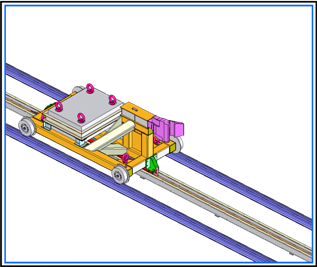

LOW-END AUTOMATED SYSTEM

OF REVERSE TYPE

FOR MOVING AND POSITIONING CARS

ASPPV-b

The system is designed for moving and positioning freight cars. It allows up to 8 empty cars be moved.

The system includes a traction module; a traction carriage with tie rod; a device for stressing a rope with hydraulic actuator; guide blocks; management system.

The peculiarities of ASPPV-b are as follows: friendly exploitation, friendly control (the availability of way sensors); relatively inexpensive cost. Preliminary lift of a heavy rod is carried out by changing tension of a traction rope with using hydraulic actuator. Final hooking is carried out by hand.

| Technical characteristics | Unit of Measurement |

Value |

| Length stroke | m | 90 |

| Traction effort (working load) | Н | 27 000 |

| Speed | m/s | 0,15 |

| Electric drive capacity | kW | 8 |

| Number of freight cars to be moved | pcs | 6 - 8 |

| Weight of the product | kg, not more than | 10 000 |

OPTIMAL AUTOMATED SYSTEM

OF REVERSE TYPE

FOR MOVING AND POSITIONING CARS

ASPPV-o

The system is designed for moving and positioning freight cars. It allows up to 8 empty cars be moved.

The system includes a traction module; traction carriage with traction a device for stressing a rope with hydraulic actuator; guide blocks; management system.

The peculiarities of ASPPV-o: improving ergonomics, friendly control, adjustable speed of movement.

| Технические параметры | Размерность | Значение |

| Length stroke | m | 90 |

| Traction effort (working load) | Н | 27 000 |

| Speed | m/s | 0,15 - 0,45 |

| Electric drive capacity | kW | 8 |

| Number of freight cars to be moved | pcs | 6 - 8 |

| Weight of the product | кг, не более | 12 000 |

If you have questions about our equipment, please contact us, our coordinates are listedon the contact page, andalsoviathe order form.