MODULES

FOR DEGASATION AND DRYNG INTERNAL SURFACES

RAIL TANK BARRELS

MDS

The problem of handling contaminated surfaces of rail carts is acute in terms of preparation of cars for repairs or change of transported product.

The range of using MDS modules– external and/or internal handling:

- tank cars for oil and oil products as oil fuel, diesel fuel, petroleum, kerosene etc.;

- tank cars for vegetable oils;

- cars and tank cars for liquefied natural gas;

- tank cars for bitumens.

One of the stages of cleaning internal surfaces of rail tank barrels id degasation. «CTG» offers special modules for conducting operations for forced degasation of internal surfaces of rail tank barrels and the following drying using appropriately prepared air.

MDS provide air cleaning from mechanical impurities and its heating (if necessary) and pumping to the rail tank barrel for drying internal surfaces.

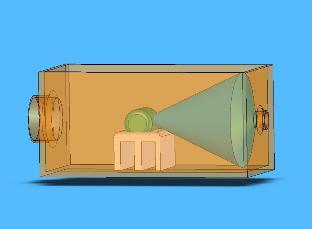

The module consists of the following parts:

- cell filter;

- ventilator;

- vapor heating device.

Operating principle of MDS: Air goes through the cell filter with the help of the ventilator; in the cell filter cold air is cleaned from dust. Cleaned air is pumped to heating device where it is heated to 50 – 70 оС. Hot air is pumped to the dried rail tank. If it is necessary to cool the tank, cleaned, but not heated air is pumped into it.

MDS are a part of complexes for drying internal surfaces of rail tank barrels of different capacities.

Technical characteristics of modules for degasation of rail tanks and gas tanks are presented in the following table:

| Main technical characteristics | MDS-01 | MDS-02 |

| Rated capacity by air, m3/h | 5000 | 15000 |

| Rated pressure of heat carrier, MPa | 0,5 | 0,5 |

| Rated temperature of heat carrier, оС | 152 | 147 |

|

Voltage, V (50 Hz) - in ventilator motor power line |

380 |

380 |

| Ventilator’s electric engine capacity, kW | 11,0 | 22,0 |

| Weight, kg | 1600 | 2800 |

Dry, saturated or superheated vapor is used as the heat carrier in MDS-01 and MDS-02 modules. Water is used in MDS-01w, MDS-02w.

MULTI-PURPOSE CASCADE FOR DRYING TRAIN SIDE SURFACES

KSNP-U

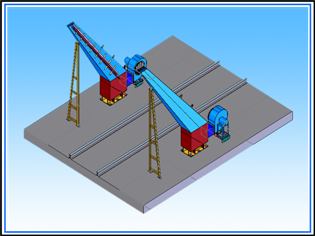

The cascade was designed for blowing-off residual moisture from external surfaces of rail tanks and cars and blowing external surfaces of cars with compressed air

The cascade consists of:

- ventilator;

- air line (blowing body);

- supporting and heavy metal structures.

| Technical characteristics | Unit of Measurement | Value |

|

Dimensions - width of each pole |

mm, not more than |

1,8 |

| Air pressure | Pa | 2200-2350 |

| Air flow rate | m3/h | 9000-11000 |

|

Rated capacity of electric drive |

kW | 11+11 |

| Weight | kg | 650 |

Cascade for drying train side surfaces

If you have questions equipment for degassing-dryingtank carsor gastanks please contact us, our coordinates are listedon the contact page, andalsoviathe order form.