EQUIPMENT COMPLEXES

FOR DE-ICING PROCESSING

OF THE BOTTOM OF THE BODY

AND UNDERFLOOR EQUIPMENT OF RAILWAY CARS

«ANTIL»

Formation of ice build-up on the bottom of the body and underfloor equipment of rolling stock can result in serious operational problems, and that’s why this issue is given a lot of attention in all countries with frosty and snowy winters addressing. With the development of express and high-speed rail transportation provision of rolling stock with effective anti-icing system becomes even more relevant. Increase in speeds activates the process of ice build-up, which when ingested gets on railroad tracks and causes when train moving various damage of underfloor equipment.

With due consideration given to market demands in respect of averting of ice built up on lower part of rail car body and underbody equipment in winter period «CTG» has developed technologies of deicing treatment.

This recirculation technology called «ANTIL» prevents the lower parts of cars and underbody equipment from corrosion and protects them fromsnow adhesion, and correspondingly, from ice built up, thus minimizing risks of emergencies caused by ice built ups and providing personnel with fast access to equipment for maintenance. Besides, disruptions of trains schedule caused by icing of the lower parts of cars and underbody equipment, as well as time required for ice removal are excluded.

The use of proposed «CTG» technology and designed «ANTIL» complex equipment makes it possible to reduce in several times, in comparison with traditional methods, both energy resources consumption and time for deicing treatment of the train. To implement this method no special premses are required – all works may be performed in the open air. Treatment process is automatic and equipment is characterized by low operational costs. Moreover, there are no special requirements for «ANTIL» equipment complex installation place. Assembling and start-up operations are performed in short period.

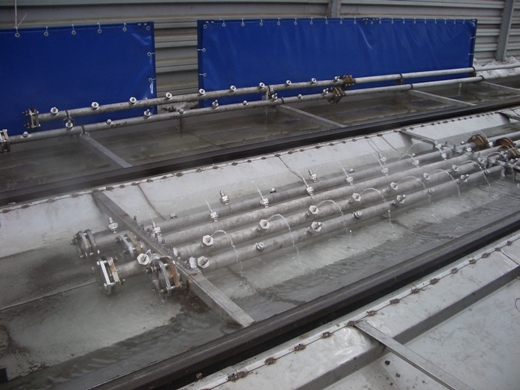

The effectiveness of deicing treatment with the proposed complex is achieved by supply of the chemi-cal agent under the high pressure on treated surface, further cleaned by removal of extra water, mud and admixtures for further use. Propylene glycol water solution heated up to 85 оС operated in recircu-lation mode, which temperature may be reduced up to 35 оС in the course of operation is used as chem-ical agent.

The proposed solution:

- Effectively – the obtained results on «ANTIL» deicing technology implementation for high-speed trains “Sapsan” underbody treatment have ensured reliable operation in the winter period. Rate of treatment speed has exceeded several times the possibilities of tra-ditional treatment by air or water.

- Cost efficient – «ANTIL» series complexes are mounted in the open air and are completely automatic, thus providing the minimum capital investments and maximum operational costs savings (energy consumption is lower than with traditional treatment by air or water in times).

- Functional – depending on problems stated «ANTIL» series complexes may have different technical “architecture”, ensuring both the preventive treatment, and removal of ice built up and snow, as well as it provides with possibility to treat only the specific places of railroad cars.

- Environmental security – «ANTIL» series complexes work inrecirculationmode, conformingto all environmental standards.

- Universally - creation of de-icing processing sites of the bottom of body, underfloor equipment and running gear of railway cars, if necessary, can be almost at all main objects - regardless of the climatic conditions.

Additional information:

Presentation on de-icing complexes of «CTG».