ENERGY EFFICIENT SYSTEMS OF

FUEL PREPARATION

VCI

It is known that heavy fuels, for the most part, are not homogeneous and fractional in composition, with non-hydrocarbon high-molecular compounds of resins and asphaltenes, resulting in destabilization and irregularity in rate of combustion. Another one result of heterogeneity is fuel separation, resulting in essential losses, degradation of operational performance and environmental characteristics. Thus, the problem of the need for fuels preparation for the combustion is of vital importance.

The most effective technology for fuels preparation for the combustion is hydrodynamical treatment (homogenization) with emulsification of containing water by means of developed, patented and implemented by «CTG» vibro-cavitation disintegrator VCI. Fuel treatment with VCI provides with possibility to prepare high-stability fuel mixtures and emulsions, which, in turn, improve operational performance and fuel combustion process, meanwhile avoiding losses and waste formation, and it also increase power and decrease the smokiness of diesel engines. The obtained homogenous texture of fuel excludes residual clusters and slugs (lens inclusions).

The proposed «CTG»’s technologies and equipment for fuel preparation by homogenization and for engine fuel mixtures preparation are recommended by Central Scientific Research Institute of the Maritime Fleet (CSRIMT), and technologies for homogenization (preparation) of fuel mixtures for boiler installations are recommended by Central boiler and turbine institute (CBTI) named after Polzunov. Many enterprises in different regions of the Russian Federation and abroad have been successfully using this technology.

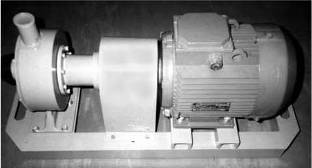

The set of this equipment is made as small emulsification and homogenization unit of continuous operation, assembled at the fuel pipe. Depending on capacity it has different modifications.

| Unit | Fuel oil flow rate, М-100, cu m/h | Engine capacity, KWt | Weight, kg | Dimensions (length, width, height), mm |

|---|---|---|---|---|

| VKI- 1V | 0,3 | 1,0 | 50 | 550х220х440 |

| VKI- 2V | 3,0 | 4,0 | 20 | 264х225х190 |

| VKI - 3B | 8,0 | 15,0 | 57 | 280х280х400 |

| VKI - 4B | 10,0 | 18,5 | 250 | 1000х600х475 |

| VKI - 4М | 20,0 | 37,0 | 360 | 1140х500х577 |

If you have questions about our energy efficient systems of fuel preparation, please contact us, our coordinates are listedon the contact page, andalsoviathe order form.