Recycling of carbon isotope

The technology is designed for the processing of weakly radioactive waste with extraction of 14C isotope of carbon for reuse. Weakly radioactive organic liquids are subjected to high temperature oxidation with two-stage multistage cooling and subsequent purification. The system includes a cleaning stage of collecting carbon dioxide, which is then chemically converted into barium carbonate and is sent to the enrichment for commercial isotope 14C.

Main advantages:

- High temperature with sufficient residence time ensures complete destruction of organic compounds.

- Complete conversion of initial carbon compounds to carbon dioxide and then barium carbonate.

- Compactness of the process equipment.

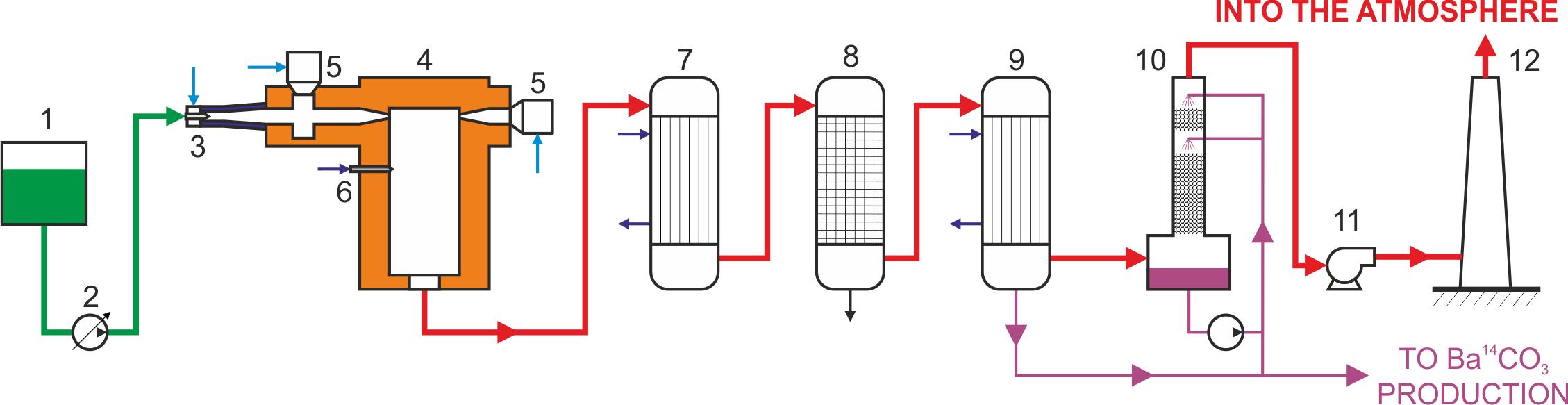

Scheme of recycling of carbon isotope

1- tank with weakly radioactive organic liquid; 2- dosing pump; 3- sprayer;

4- two-stage high temperature reactor; 5- generator of high temperature oxidizer flow; 6- sprayer;

7- quencher; 8- filter; 9- heat exchanger; 10-absorber of carbon dioxide; 11- exhaust fan; 12- stack.

Waste containing radioactive carbon isotope 14C are formed during the use of tracers in the biomedical industry and scientific researches (in medicine, biochemistry, microbiology, molecular biophysics, etc.). They represent different kinds of organic liquids (including solvents) with substituted carbon atoms and laboratory supplies (gloves, cloths, glassware, aids, etc.) or sorbents (vermiculite, silica gel) with traces of such liquids. Currently, waste containing this isotope are accumulated, specially packaged and stored in designated areas. Due to the constant tightening of legislation norms governing the treatment of radioactive waste and increasing of negative public opinion of the population living in the vicinity of special storage places, there is a need to create a cost effective and environmentally friendly technology for the processing of this waste with extraction of 14C for secondary use.

Thermal processing of weakly radioactive waste has traditionally been made by FSUE "Radon". The company has a number of plants for processing liquid radioactive waste by thermal methods, including plasma. Radioactive substances are accumulated in ash with further encapsulation in resistant matrices for transportation and storage. Recycling of isotopes is not offered.

Output on waste — 150 kg / day.

Power consumption — 50-75 kW.

Estimated cost of the installation is 500 thousand USD.

Project implementation period — 18 months.

If you have questions about our technology, you can ask them by e-mail: spb@ctg.su.