WASHING COMPLEXES

INTERNAL SURFACES

FOR FIXED CONTAINERS

Containers cleaning is a worldwide issue that is solved by exposing of superheated high-pressure steam onto dirty surface that obviously requires huge energy sources.

But there is a way ultimately different from the traditional one. There is no need to spend much money for creation of a treatment system of surfaces with high quality and cleaning of polluted runoffs and harmful vapors and then spend more expenses for maintenance. It is possible to treat surfaces with fewer costs and not discharge anything in sewerage and not to clean them. Such treatment systems where a surface is well cleaned under low temperatures without runoffs were created in «CTG» company.

INTERNAL WASHING COMPLEXES

FOR FIXED CONTAINERS

OF CONSIDERABLE VOLUME

KVO-StR-zo

The cleaning process of cylindrical vertical and horizontal, surface and subsurface fixed tanks of significant volume is usually complicated by presence of heavy bottom sediments.

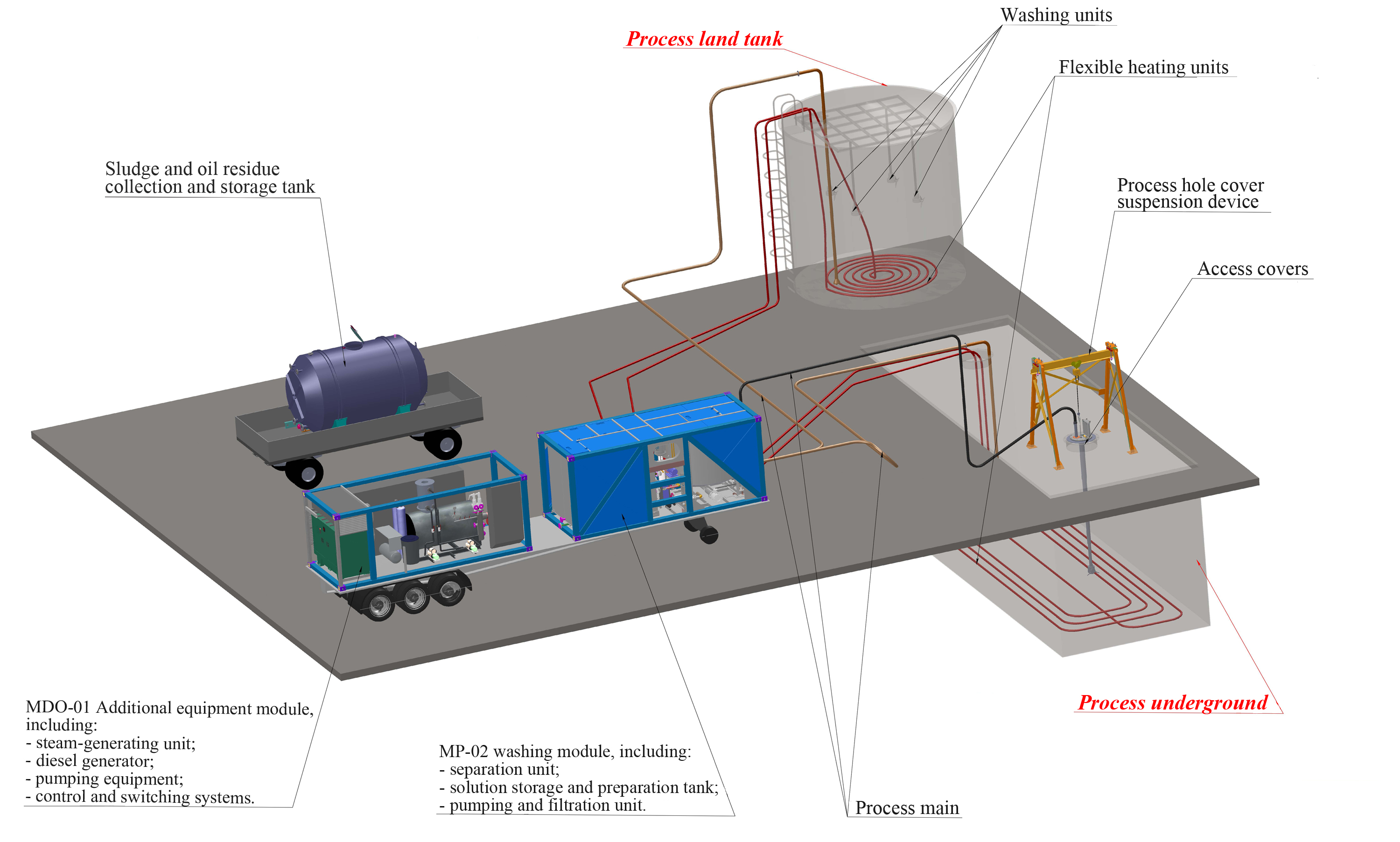

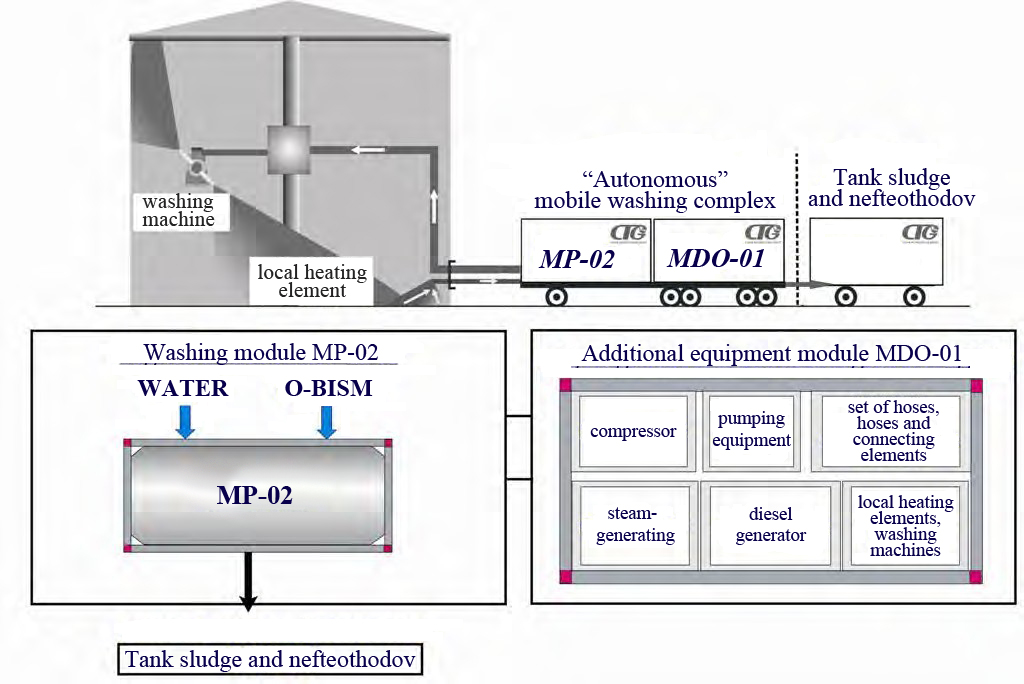

The proposed complex of process equipment, which provides cleaning and washing of fixed tanks of significant volume, consists of washing module (MP-02) and additional equipment module (MDO-01) and also the capacitor module for collecting sludge and oil residues. These modules and tank are placed inside a 20-feet container, which, in turn, can be installed on container vehicles, enabling rapid move to objects of washing.

Washing module MP-02 includes all main systems providing engineering process of tank washing, namely, preparation and purification of detergent, delivery of detergent to the surface to be washed, pumping out to the module for separation, etc. Additional equipment module MDO-01 has: steam generator, compressor, diesel power plant, pumps, and washing machines with fittings, a set of hoses, sleeves and connecting elements, local heaters etc.

Principle diagram of KVO-StR-zo

Operating costs of KVO-StR-zo

|

No. |

Equipment name |

Efficiency |

Consumable resources |

| 1. |

Steam generator |

Steam 1000 kg/h Pressure 1-16 bar |

Diesel fuel 60 l/h, water 1000 liters for initial filling, water consumption for topping up to 50 liters/hour; electricity 2.7 kW |

| 2. |

Diesel generator |

Electricity 380-440 V, 50 Hz, Nominal 40 kW/h |

Diesel 13 l/h |

| 3. |

Compressor |

Compressed air 320 l/min, pressure up to 10 bar |

Electricity 3.0 kW |

| 4. |

Water consumption for initial filling of module MP-02 |

|

15,00 m3 |

INTERNAL WASHING COMPLEXES

FOR FIXED CONTAINERS

OF SMALL VOLUME

KVO-StR-no

For cleaning and washing of tanks of a relatively small volume of tank, such as subsurface tanks at petrol stations, we offer complex of equipment which is mini mobile washing station (MMWS).

MMWS is a converted lorry based on tanker truck (sewage tank trucks, gasoline tank truck etc.). Vehicle with MMWS is equipped with two tanks, or with one tank, divided by a partition into two parts and equipment required for operation (pumps, washing machine, sleeves, etc.). Car loads in one of its tanks (compartments) detergent of «O-BIS» series and moves to the place of processing. On Installation of equipment is made on the site, as shown in the diagram below, and washing and cleaning is performed. Pumping out the contaminated solution is made to the empty tank (compartment) of MMWS. Released oil products and sludge are transported to the place of accumulation and pumped into a separate tank for subsequent neutralization and recycling, and the purified solution is regenerated for subsequent processing cycles.

Principle diagram of KVO-StR-no

Designations:

1 – washed tank for petroleum products storage;

2 – washing machine;

3 – nozzle;

4 – MMWS for clean «O-BISM» solution delivery to tank 1, and for separation of cleaned petroleum products and «O-BISM» solution;

5 – tank for decanted oil products discharge.

If you have questions about our washing complexes, please contact us, our coordinates are listedon the contact page, andalsoviathe order form.