Destruction of liquid toxic wastes

The technology is intended to guarantee the destruction of especially toxic liquid waste: polychlorinated biphenyls; halogen-containing hydrocarbons and other substances; freons; chemical warfare agents and their products; other liquid toxic waste.

Liquid wastes are injected into the tunnel reactor where they are ignited and burned at temperature of 1200-1300 °C. Flue gas is then fed into a vortex reactor, where at 1400-1500 °C and at a significant residence time there is a final oxidation and mineralization of the organic matter. Flue gases from the reactor are quenched and fed to multi-stage cooling and cleaning system. The installation can be applied in the area of local formation or accumulations of liquid toxic waste.

Main advantages:

- High temperature with sufficient residence time ensures complete destruction of resistant organic compounds.

- Compactness of the process equipment.

- High environmental friendliness

Scheme of process of destruction of liquidtoxic wastes

1 - liquid toxic waste; 2 - inflammable solvent (if necessary); 3 - water; 4 - dosing pump;

5 - multicomponent sprayer; 6 - two stage reactor; 7,8 - generators of high temperature oxidizer flow; 9 - pneumatic sprayer;

10 - system of quenching and cooling of the destruction products; 11 - gas treatment system; 12 - exhaus fan; 13 - stack.

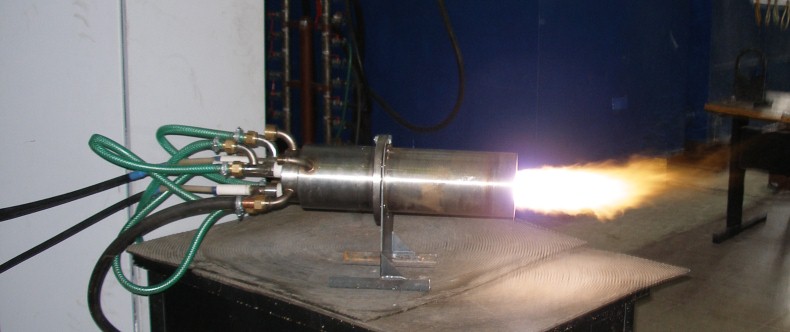

General view of two-stage reactor and supply system

Generators of high temperature oxidizer flow

Comparison with traditional methods

|

Company |

Output |

Area |

Cost |

|

kg/h |

m2 |

Million rub. |

|

|

Turmalin |

50 |

200 |

from 12 |

|

TechEcoPlasma |

up to 100 |

60 |

No data |

|

Plazarium |

50 |

70 |

No data |

|

Proposed «CTG» |

50 |

30 |

10 |

Output on waste — to 50 kg / day.

Power consumption — 50-75 kW.

Estimated cost of the installation is 150 thousand USD.

Project implementation period — 18 months.

If you have questions about our technology, you can ask them by e-mail: spb@ctg.su.